Manufacturing

Handy Stands can be used in schools, offices, retail stores, and other public places. With the convenience of a handheld hand sanitizer, you can keep those around you safe.

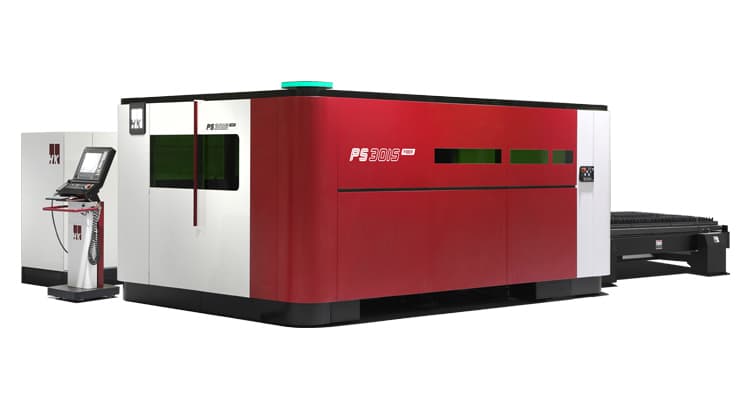

As a global manufacturing company with a commitment to customer satisfaction, GSS Machinery successfully complies with modern quality standards.